Smart Finishing series

In the past few years, many customers have tried to deal efficiently with the ever smaller print runs by using a digital printing machine. This is a useful first step: it replaces an analogue with a digital process. Set-up times, start-up waste, tool procurement, storage and recycling are further issues that can and must be addressed. ALS Engineering considers the whole digital value-adding process, starting with the end product and ending with the production of the label form in the pre-press stage.

Smart core

The final conversion to the right roll core widths for differing orders on large rolls often presents challenges. SmartCore (width 330-500mm) is an automatic roll core cutter which receives the cutting information from the order system, e.g. from a laser die-cutter. Wrong cores become a thing of the past.

Smart rewinder

With a semi-automatic rewinder on the laser die-cutter, the operator can dispense adhesive onto cores after automatic cutting, apply a two-sided adhesive tape, then place the lengths cutting web on the core spindle in around 5 seconds and proceed to the next order.

Smart slitter

Automatic adjustment of the slitter knives enables you to change orders in seconds, with no manual intervention, using barcode control in combination with the laser die cutter and digital printing system. The laser die cutter runs continuously thanks to the upstream material buffer. Up to 700 different orders a day can be processed and delivered.

Smart buffer

A variable material buffer with max. 30 metres of storage volume provides for continuous production of self-adhesive labels.

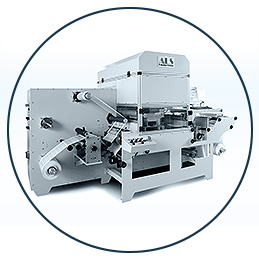

Varnishing systems

ALS Engineering GmbH builds robust flexible varnishing systems of simple design with print cylinders with a sleeve design. By upgrading to a multi-varnishing system, you can use bar code controls to change the varnish ‘on the fly’ without retooling. This is especially useful where the varnish has to be changed frequently in the online printing business, and can be extended to other applications such as folding boxes or book covers as required.

Laser die cutters

Laser die cutting systems are part of ALS Engineering GmbH’s core business. There has been an enormous increase in the speed and accuracy of contactless finishing. Restrictions on the choice of material and the cutting quality have ceased to be an issue over the past few years. ALS Engineering GmbH has developed proprietary control software that can hugely increase the number of possible applications for laser systems. If you would like to cut special materials, talk to us or request samples.

Digital printing systems

For digital printing, ALS Engineering can offer a proprietary system based on the single-pass inkjet principle: the ecojet digital printing system. The latest printing head technology delivers very high print quality, with high resolution and at a cost-effective speed. A proprietary software solution with every imaginable option for colour management ensures high-end print quality. The ecojet printing system is a modular system and can be supplied in a range of print widths and colour combinations. Combining it with a laser die-cutter enables full digital production. Printing plates and cutting tools are no longer required. Software controls also enable automatic form changing.

Software

ALS Engineering GmbH develops its own proprietary control software for integrated, process-optimised operation of total systems. Open interfaces to MIS systems and to camera systems for optical production control are available.

ALS works with the multiple award winning software AEPOS by Lewald & Partner in the area of automation for print form design and order control.

This enables you to individually activate, track and convert every label or every folding box using a barcode. The modules downstream from printing, varnishing, coating, punching and cutting permit individual handling of every label and every folding box fully automatically in accordance with rules set up front.